The company has implemented a Quality Management System according ISO 9001, ISO 14001 and ISO 45001

The company has realized a project under the Sectoral Operational Programme

"The Increase of Economic Competitiveness in 2004-2006"

co-funded by European Regional Development Fund.

The Roadheader VT-100 is a self-propelled rock cutting machine for driving galleries (headings, tunnels). The roadheader can be operated in underground headings of mining facilities, also excavating hard coal, including headings with “a”, “b” or “c” methane explosion hazard degree and class A and B coal dust explosion hazard. The roadheader enables driving a heading of any shape and width (operation under several settings), over a height range from the loading table level to the maximum range of the cutting drum (i.e. approx. 4,3m from one setting). It is also possible to drive higher galleries when applying appropriate technologies, compliant with the mining art and regulations.

The Roadheader can also be used for dinting and grading of piled-up reproduced headings, as well as for reconstructions of existing galleries – both for cutting, as well as loading the excavated material.

The Roadheader is adapted for operation in gas explosive areas, mainly in hard coal mines, while it can also be operated in mining of other mineral raw materials (e.g. halite), provided that the conditions of use specified in this manual are satisfied.

TECHNICAL SPECIFICATION

General parameters:

Max. hardness of worked rocks: 60MPa

80MPa (przy ilości <10% within the cross-section),

In the presence of more than 10% of rocks with a strength of 80MPa within a cross-section - additional mining with the use of Explosives to be used, and the roadheader used to outline the working and load the output.

Max. transverse inclination of a driven heading: ±10°

Max. longitudinal inclination of a driven heading: ±18°

Max. longitudinal inclination of a dip driven heading

with the use of equipment supporting

Roadheader operation (e.g. SU.VT): -35°

Max. dimensions of lumps loaded onto the

to a scraper conveyor: 40x40x40 cm

Roadheader dimensions:

Width: 2000÷3000 mm depending on the loading table version

Height (without the working platform): 1935 mm (drum set vertically)

Length: 8115 mm

Roadheader weight: 29,25 Mg

Maximum power installed on the roadheader: 169 kW

Supply voltage: 500V / 1000V

Unit pressure on floor: 110 kPa

Working capacity (theoretical): 10÷40m3/h depending on rock hardness,

mining-geological and organizational conditions

Operating temperature: +10° ÷ +40°

Maximum transverse cross-section of a driven

heading from a single setting 22m2

maximum upward reach of the drum 4 300 mm

maximum undercut of the floor with the drum 150±50 mm

maximum deflection of the drum to the side (from the axis) 2 550 mm

Maximum transverse cross-section of a heading to be executed from a single setting.

Cutting drum motor type: 4SGP 280-4 DAMEL or dSKK200L4A CELMA

Motor power: 100 kW

Motor rotations: ~1470 min-1

Supply voltage: 500V / 1000V

Cooling: water or other consistent with Operation and maintenance manual (Electric Part)

Cutting drum gear type: L-100V (GLIMAG, REMAG)

Gear ratio: 19,903

Cutting drum rotations: 73,8 min-1

Seal on output shafts: GOETZ lub SIMMERING

NOTE: cutter heads can be ordered in two execution versions adapted to the tightening of the output shafts of the cutting drum gear

Number of cutter heads: 2 pcs

Head setting: transversely to the drum longitudinal axis

Picks per head (standard version): 2 x 48 pcs

Type of picks: U-47 140/65/65/38/30 (carbide fi22 lub fi25) or equivalent (KENNAMETAL, GONAR, VENITEC)

Pick shank diameter: Ø30mm/ Ø38mm

Pick holder type: U-43H or equivallent (KENNAMETAL, GONAR, VENITEC)

Head diameter along the pick edge contour: 740mm

Total cutting width (two heads): 1220mm

NOTE: other execution versions of the heads with pick holders and picks are permitted, upon consent from the manufacturer, i.e., VACAT Sp. z o. o.

Loading table:

Type: wedge type loading plough with two loading arms, lifted hydraulically

Number of lifting cylinders 2 pcs

Table lift height: +160mm -100mm

Type of gearbos for load lugs: the drive gear of the roadheader's scraper legs AM-50 (GLIMAG, REMAG)

Gearbox seal: GOETZ or SIMMERING

Loading arm drive: scraper conveyor return drum

Loading table width: 2000 mm

Width after installing

widening extensions (optional): 2500÷3000 mm

Scraper conveyor:

Width: 460 mm

Length (Between drums) 5790 mm

Theoretical efficiency: 60 t/h

Chain speed: 1,0 m/s

Drive: 2x13 kW electric

Chain route: 2x(18x64) or 2x(19x64)

Scraper spacing: 384 mm

Motor type: 3SGK 160S-4 DAMEL or STKg160S4 CELMA

Motor revolutions: ~1460 min-1

Voltage: 500V / 1000V or other consistent with Operation and maintenance manual (Electric Part)

Gear type: AM-50 Roadheader conveyor drive 11/13 reducer (GLIMAG, REMAG) i=13.229 or

PNP-15 (GLIMAG) i=13.32

Travel system:

Type: crawler track drive, electric

Number of tracks: 2 pcs

Track width: 520mm

Number of elements per 1 set: 51 pcs

Track connecting pin diameter Ø27mm

Travel speed: 0,1m/s

Track drive: independent electric 15kW+15kW

Motor type: 3SGKH 200S-4 DAMEL with brake or dSTKg200S4-h CELMA with brake

Motor revolutions: ~1460 min-1

Voltage: 500V / 1000V or other consistent with Operation and maintenance manual (Electric Part)

Track drive gear: Running gear reducer 15/256 (GLIMAG, REMAG) i=256.2

Hydraulic system:

Hydraulically supplied elements:

1) loading table raising (2 cylinders)

2) cutting drum raising (2 cylinders)

3) cutting drum pivoting (2 cylinders)

4) stabilizer strutting (1 cylinder)

5) supply of additional equipment (additional outlet)

Tank capacity: 240l

System capacity: 250 l

Medium type: hydraulic oil HLP 46 lub HLP 68

System type: otwarty

Cooling: water (open water system with spraying, supplying the exchanger in the tank, optional

extra water cooler on the tank oil discharge)

Unit power: 13kW

Unit operating capacity: 30l/min

Maximum system pressure: 20MPa

Motor type: 3SGK 160S-4 DAMEL or

STKg160S4 CELMA

Motor revolutions: ~1460min-1

Voltage: 500V / 1000V or other consistent with Operation and maintenance manual (Electric Part)

Hydraulic pump type: A7V0 55 or A2V55 or PVO32

Hydraulic connections: STECO or threaded (”screwed”)

Permissible oil temperature during operation: 80°C

List of cylinders:

|

Section |

Qty. |

Spacing between lugs / stroke [mm] |

Piston diameter/piston rod inner diameter [mm] |

|

raising and lowering of the cutting drum boom |

2 |

1159-1715/556 |

80/135 |

|

pivoting of the cutting drum (left-right) |

2 |

x/+-155 |

170/170 |

|

raising and lowering of the loading table |

2 |

441-546/105 |

80/120 |

|

raising and strutting of the stabilizer |

1 |

260-610/350 |

80/120 |

Cooling and spraying system:

The cooling system covers: 1) 100kW cutting drum motor

2) hydraulic unit tank (oil cooler)

3) optional cooler installed on the oil tank discharge

System type: open with spraying outflow

Spraying system: external, 13 nozzles on the cutting drum

external, 2 nozzles on the scraper conveyor discharge

Nozzle type: KSTK®/IR (diameter 2mm)

Single nozzle capacity: 5,1l/min at 10bar

Required minimum amount of water in the system: 50l/min

Required water pressure in the system: 10÷22bar

Water filtration: min 100 μm

DESIGN

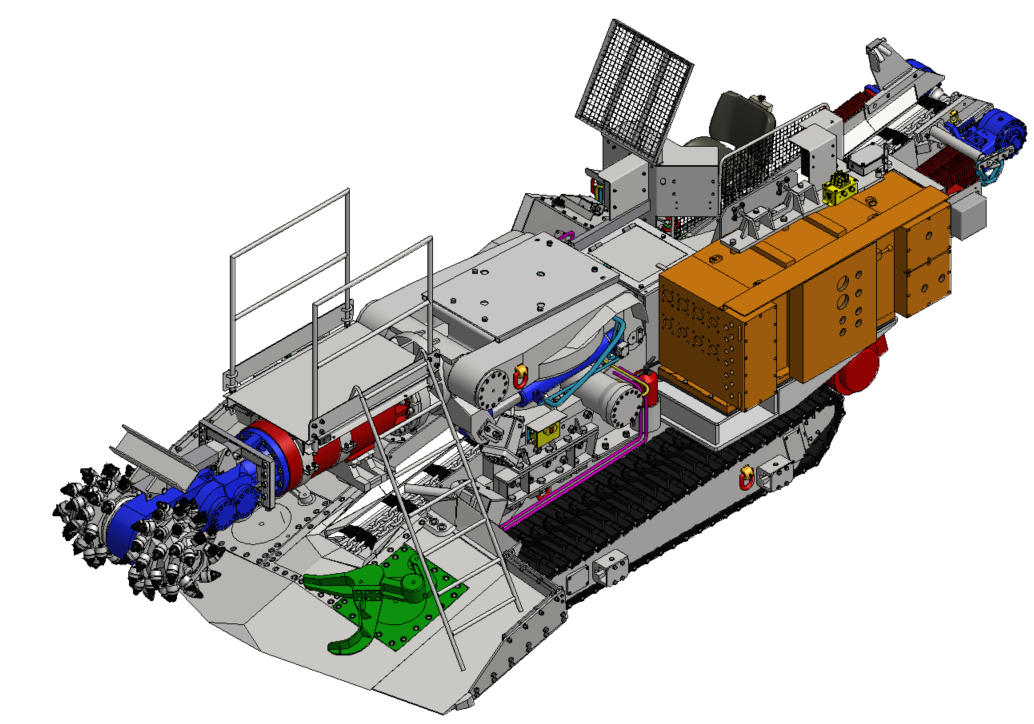

The Roadheader VT-100 is a self-propelled driving machine with an electric drive, boom-type, designed for driving galleries. The cutting drum is placed on a boom, which enables its movement in the horizontal and vertical planes within the driven heading face. The roadheader is set on a crawler chassis enabling its independent movement and positioning within the face area. The basic mechanisms and sub-assemblies of the roadheader have an electric motor, i.e., the cutting drum, chain feeder with loading gears of the loading table, crawler travel mechanism. The roadheader also has an electrically powered hydraulic unit, which supplies cylinders for moving the cutting drum, raising the loading table and strutting the stabilizer.

The roadheader VT-100 consists of the main sub-assemblies listed below:

|

Unit Name |

Description |

|

Cutting drum |

Cl. 5.1. |

|

Loading table |

Cl. 5.2. |

|

Scraper conveyor |

Cl. 5.3. |

|

Supporting frame with drive mechanism |

Cl. 5.4. |

|

Turret |

Cl. 5.5. |

|

Stabilizer |

Cl. 5.6. |

|

Control stand |

Cl. 5.7. |

|

Hydraulic system |

Cl. 5.8. |

|

Cooling and spraying system |

Cl. 5.9. |

|

Power and control system |

Cl. 5.10. |

Pic. 5.1. Design of the roadheader VT-100.

In order to ensure haulage continuity, the roadheader has a connection plate in the rear part under the chain loader for connection with face haulage equipment, i.e., a scraper or belt conveyor. The roadheader power supply system enables the connection and roadheader box control of one or a maximum of two drive motors of a short loader behind the roadheader, up to 15m long and a capacity of max 2x22kW.